Prepare the rig for the new sailing season

It's almost time to get back on the water! So quickly tackle the final work and get the sailing boat or motor yacht ready for the new season. In this guide we give you helpful tips for the preparation and care of the rigging.

1. Standing rigging

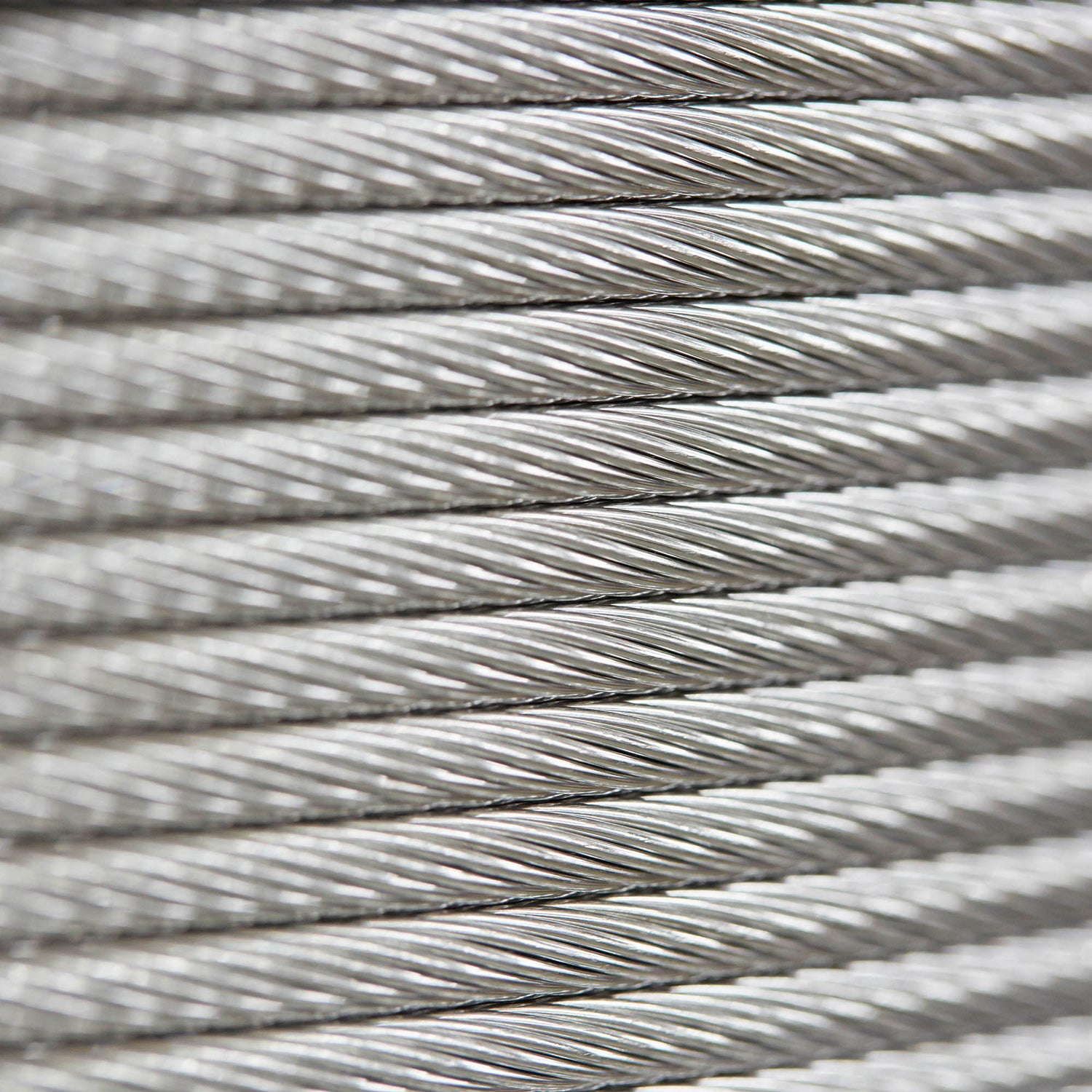

First we take care of the standing rigging. The stay made of stainless steel wire is an elementary part of the rigging and relevant for safety at sea.

1.1 Check shrouds and stays

1.2 How to check the standing rigging

Kinks and cracks in the individual twisted small wires find rusty spots or worn areas discover the connection to the eye or fork terminal shows signs of corrosion or can no longer be fully tightened in the case of a threaded terminal because the Allen screw (Iska) is choked on the wire pressed rolling terminal individual, small wires of the assembly are already broken or the wire unraveled or unraveled With a shroud tension meter you can also easily check whether the rigging is holding securely

2. Moving rigging

Of course, where there is movement, materials are worn out. And mostly where the eye of the beholder is not always present. In the case of the halyards or sheets, it is usually the areas where the cordage runs around the corner, e.g. over a pulley.

2. Check the remaining cordage

Check the ends of the sheets and other cordage. Are the ends closed? If necessary, they should burn them down. Check for split ends and whether the cordage has been severely worn. It should feel supple but still stable.

3.1 Mooring lines, anchor lines and towing lines

When it comes to mooring lines, especially on a newly purchased boat, you should check that the correct cross-sections are used for the specific requirements. Depending on the length of the ship, we recommend appropriate diameters for mooring, anchor and towing lines.

Calculation support

| Boat length (m) | 6-8 | 10 | 12 | 14 | 16 | 18 |

| Mooring line diameter (mm) | 10 | 12 | 14 | 16 | 18 | 18-20 |

| Anchor rope diameter (mm) | 12 | 14 | 16 | 18 | 20-22 | 22-24 |

3.2 Wash or clean cordage

If it has been checked beforehand that the ropes will last another season, they only need a little care. You can use simple and inexpensive means to bring ropes, sheets and halyards back into shape. The advantage: deep-seated sea salt disappears, dirt and oil are gently washed out.

Note: Some manufacturers advise against washing your cordage yourself in the machine because the softeners also dissolve, so that the cordage feels soft after washing but later becomes harder again.

When cleaning the cordage, make sure to...

- remove all shackles and pulleys beforehand

- not wash the cordage at temperatures above 30 °C u

- se normal washing powder or one for functional textiles

- use a laundry bag, especially with thin ropes, otherwise they may get caught in the edge of the drum

- shoot up the ropes and secure them. That way you don't have to spend hours untangling them later

- air dry the ropes,

Our tip: Old pillowcases with zippers are suitable for cleaning cordage.

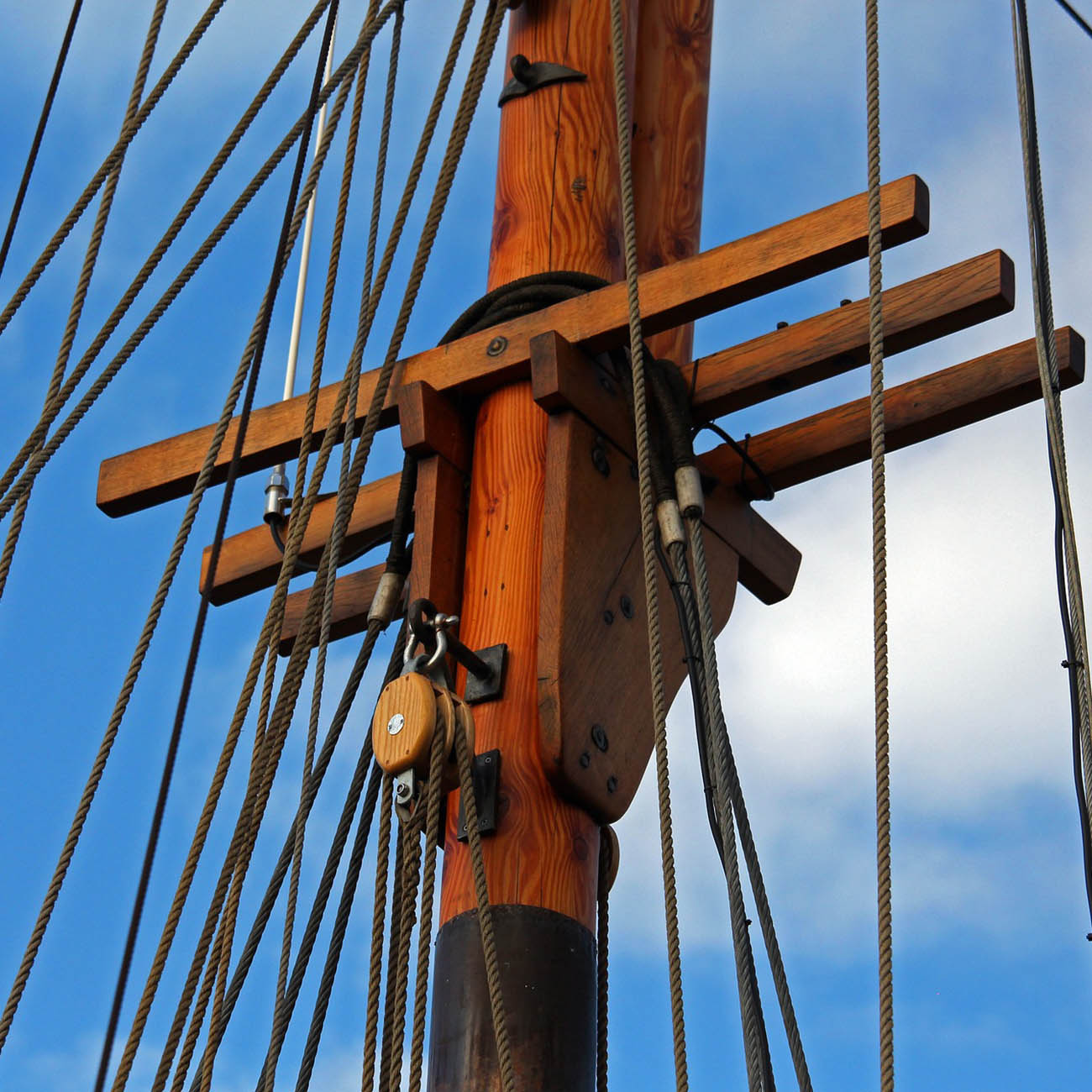

4. Maintain and prepare sail mast

A well-maintained sail mast is crucial for a successful and safe sailing trip. But how do you actually care for a sail mast? In this article you will find valuable tips and tricks to keep your mast in top condition and avoid damage.

4.1 Aluminium-Mast überprüfen

With an aluminum mast, you have less work to do in the pre-season, because an aluminum mast is maintenance-free. Only those who want to get the surface nice and smooth or shiny can paint it at a certain frequency or even polish it from time to time. In addition, a complete inspection should also be carried out on a sail mast made of aluminum to see whether the surface is free of cracks and the pop rivets or screw connections are intact.

4.2 Maintain wooden pole

Bei einem Mast aus Holz ist wesentlich mehr Pflege erforderlich. Überprüfen Sie verschraubte Stellen darauf, ob Nässe eingedrungen ist und die Beschläge zu stark beansprucht wurden - vielleicht sogar bereits ausgerissen sind. Auch gilt es zu überprüfen, ob das Holz stark angegriffen wurde, weil an manchen Stellen vielleicht der Klarlack abgeschürft wurde. Zu einer umfassenden Pflege eines Holzmastes gehört auch das regelmäßige Schleifen und Lackieren. Nur so lässt sich gewährleisten, dass keine Gischt oder Regen in das Holz eindringen und es aufweichen. Dafür könenn Sie den Mast sicher auf Böcke legen und zum Schleifpapier greifen.

Once the mast has been laid...

...you can take advantage of the moment and check all the supply lines to the radar, lamps, antennas and the associated connections and cable connections on the masthead and in the supply line. Such spots also like to corrode, come loose or chafe due to the swinging of the mast. If some of the cables are laid too close together, they may be under too much tension. If necessary, you can re-route, re-tighten and clean connections. In addition, you can lubricate the rollers and blocks in this condition.

5. Inspect idlers and blocks

To keep the rig and its pulleys in good shape, they should be nicely lubricated for smoothness. Blocks, clamps & rollers must be checked for mobility. A boat silicone spray is recommended for this. Often a few small sprays on the vulnerable areas where there is the most friction are enough. Please also make sure that the plastic rollers in the deflectors for halyards and straighteners are fully functional. You are often attacked by water and sun over a long period of time. So if the surface is cracked or the edges are chipped, they should be replaced. If they are not available as spare parts, you will drive more safely if you replace the entire fitting. Otherwise it is possible that the small plastic particles get stuck in the cordage or in your hand afterwards. As part of these checks, you should also examine the clamps and fall arresters.

6. Test winches for functionality

Schotwinschen, Ankerwinschen & Überprüfen Sie Fallwinschen auf Funktion und Leichtgängigkeit. Dabei elektrische oder hydraulische Winschen zusätzlich auch mit manuellen Kurbel drehen und eine testweise auf Spannung gelegte Schot dicht holen. Bei Bedarf sollte man die Klinken und Federn erneuern – sie gehen meistens im Winter kaputt. Nutzen Sie spezielles Winschenfett um die Gängigkeit zu erhalten und ein Verschleißen zu minimieren. Spätestens vor der ersten Ausfahrt sollte überprüft werden, ob die Winschkurbel an Ort und Stelle ist, weil sie gerne mal im Winterlager verschwindet oder über Bord geht.